Chevrolet | Corvette : April 11, 2020

Alan brought us his 2007 Chevrolet Corvette Z06 to address the LS7’s infamous valve drop issues, add another 100whp+ worth of naturally aspirated power, all while maintaining optimal driveability!

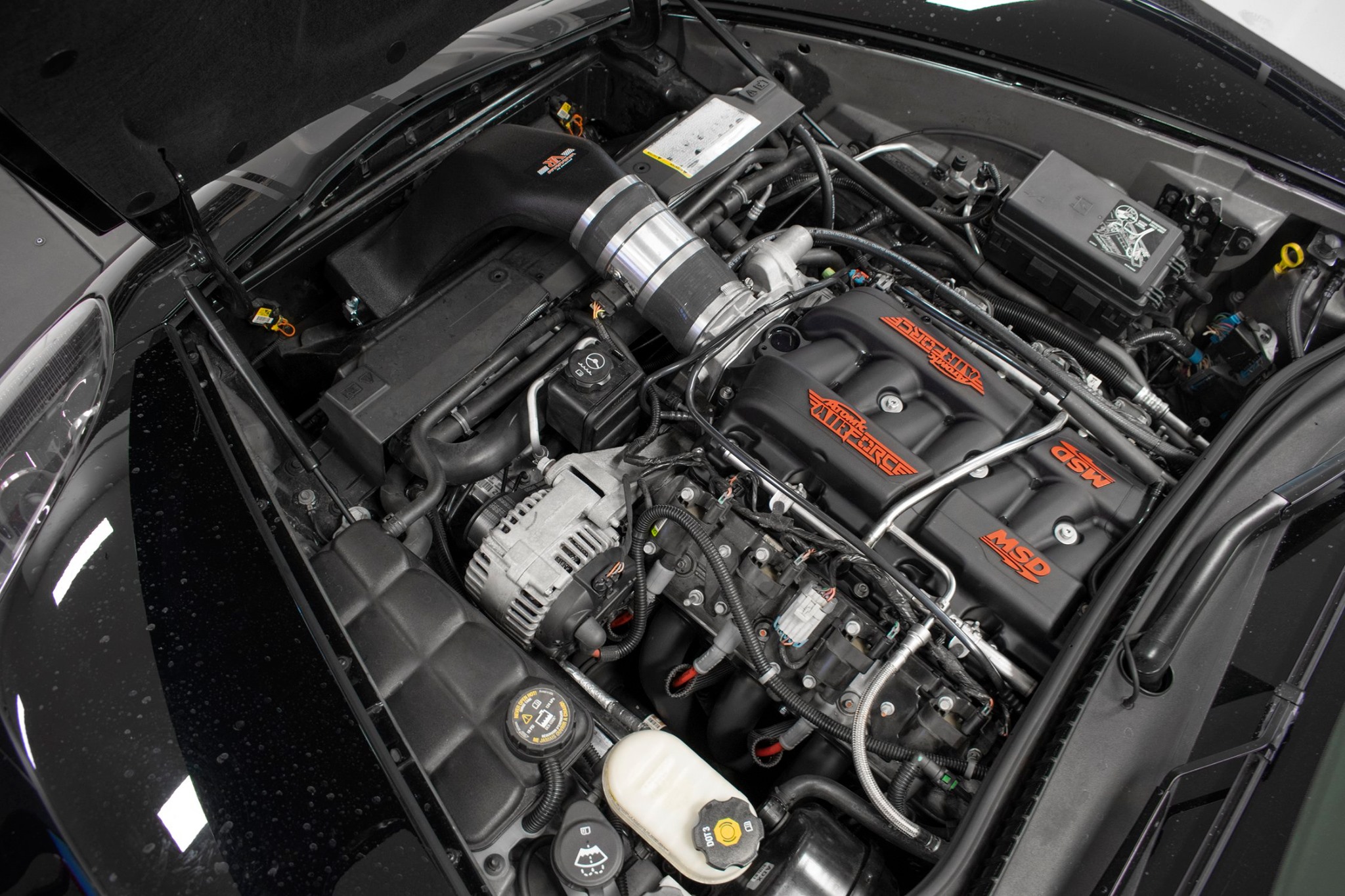

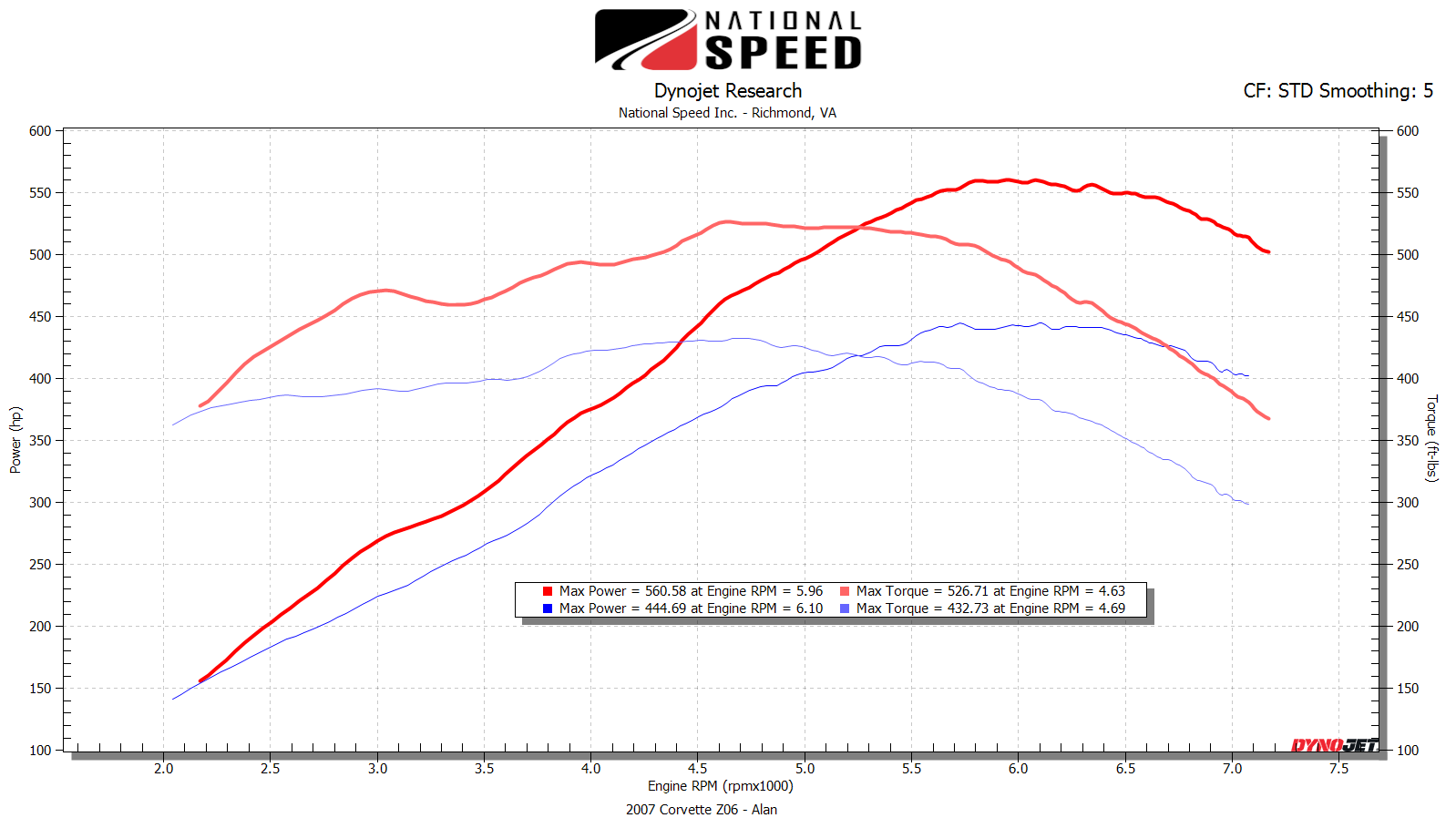

Up first, John performed baseline dyno runs to establish our starting point, coming in at 444.69whp & 432.73lbft. Then in the shop, Louis disassembled the LS7 to the short block and reassembled with a set of CNC ported cylinder heads from Lingenfelter Performance Engineering, a custom billet-core camshaft from Cam Motion designed with a goal of optimal drivability over peak power, valve springs from Brian Tooley Racing, pushrods from COMP Cams, rocker arm bronze bushing trunnion upgrade from Smith Brothers Pushrods, fasteners from ARP, SC1R intake system from Vararam Industries, 2.00" primary OD long-tube headers from Stainless Works Cerakoted by Detective Coating connected to a Chambered Turbo axle-back exhaust from Stainless Works, spark plug wires from MSD Performance wrapped in Protect-a-Boots from Design Engineering, Inc., 160° thermostat from Lingenfeld, topped off with an Atomic AirForce intake manifold from MSD Performance, all brought together with new OEM GM gasket, seals, fluids, and timing components (along with a C5R timing chain).

With the mechanical work wrapped in the shop, John strapped her down to the rollers for Vlad to perform a custom calibration via HP Tuners. The results? 560.58whp & 526.71lbft -- a gain of 115.89whp & 93.98lbft! Tons of usable power for both the street and track, and yes, all while delivering that optimal drivability Alan was after.